ESAF TradeCo

Innovative Solutions

Innovative Solutions

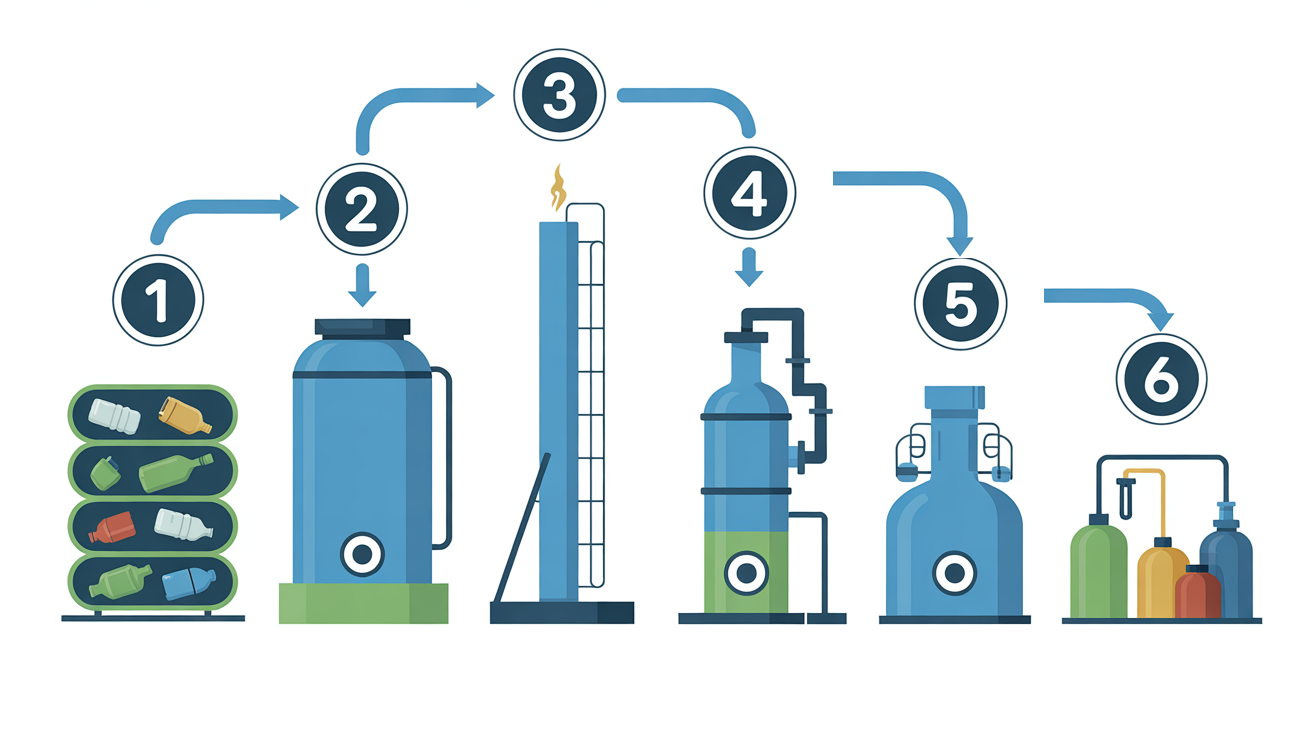

Multi-stage catalytic refining process converting plastic waste into specification-grade aviation turbine fuel and diesel, meeting ASTM D1655 and EN 590 standards

Six integrated stages transform plastic waste into clean, sustainable fuel

| Stage | Process Step | Description |

|---|---|---|

01 | Plastic Waste Sorting & Shredding | Post-consumer PE, PP, and PS plastics are sorted and shredded to <20mm particles |

02 | Thermal Pyrolysis | 400-500°C thermal depolymerization under inert atmosphere produces condensable hydrocarbon oil |

03 | Fractional Distillation | Separation into naphtha (C₅-C₉), kerosene (C₁₀-C₁₅), diesel (C₁₅-C₂₀), and wax fractions |

04 | Hydrotreating | NiMo/CoMo catalysts remove sulfur, nitrogen, and oxygen while saturating olefins and aromatics |

05 | HydroisomerizationPATENTED INNOVATION | Pt/zeolite catalyst converts n-paraffins to iso-paraffins for improved cold-flow properties |

06 | Blending & Quality Control | Final product meets ASTM D1655 (Jet A-1) and EN 590 (Diesel) specifications |

Proven performance metrics validated through pilot-scale testing

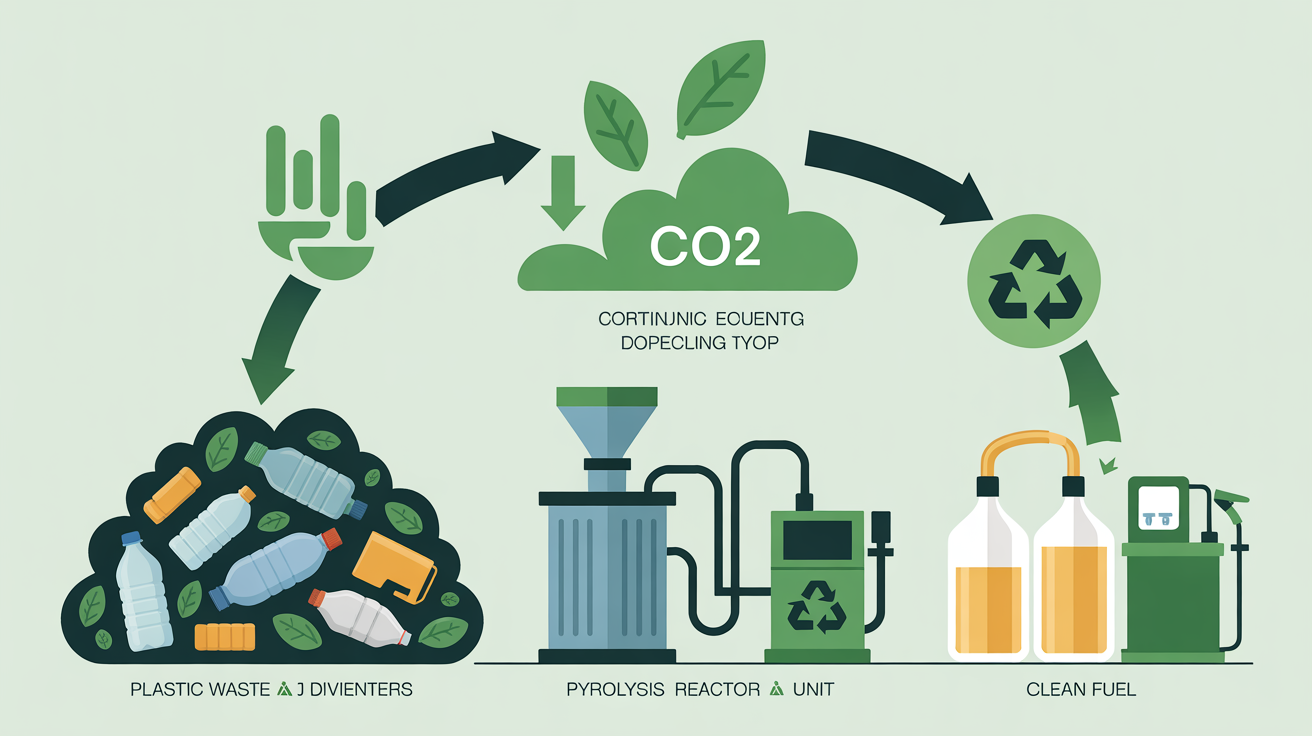

Transforming plastic waste into clean fuel while dramatically reducing greenhouse gas emissions

ESAF TradeCo works closely with Verra to develop dedicated methodologies for carbon credits and plastic credits issued from pyrolysis with plastic recycled feedstock, ensuring maximum environmental and economic value.

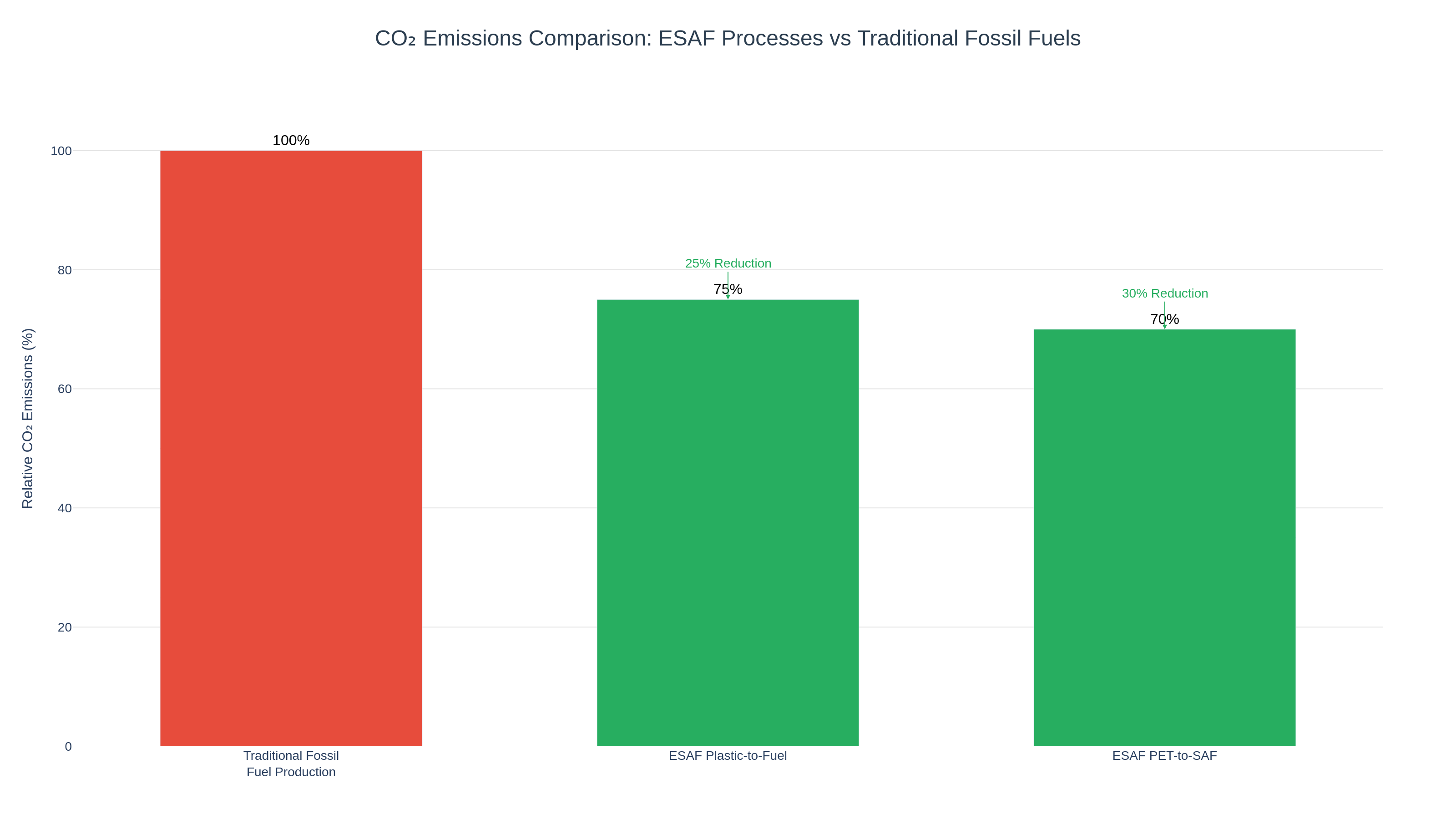

Patented process advantages that set us apart from conventional approaches

vs. fossil fuel production

liquid fuel from plastic

meets all aviation standards

100% feedstock utilization