ESAF TradeCo

Innovative Solutions

Innovative Solutions

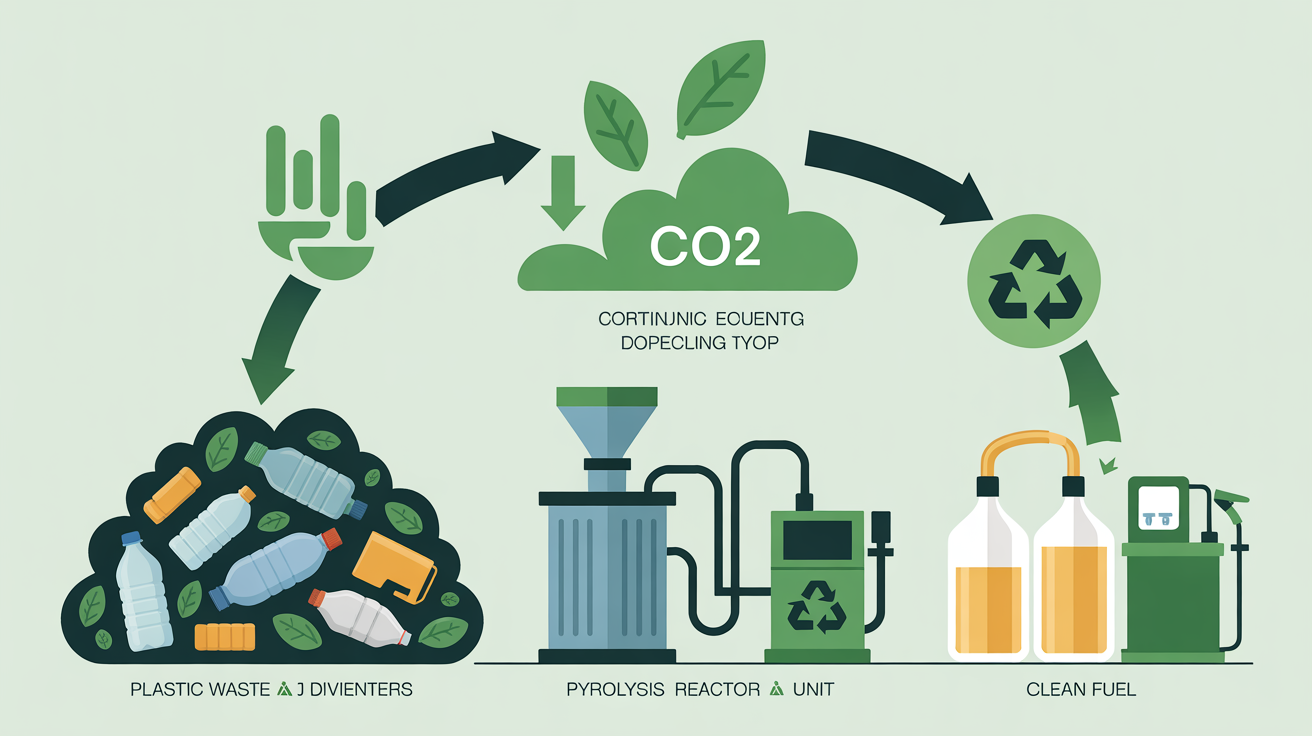

Revolutionary hybrid chemical-thermal process enabling high-PET-content plastic waste (15-50%) conversion to ASTM D7566-certified sustainable aviation fuel through staged catalytic pyrolysis

Integrating chemical pre-treatment with advanced catalytic pyrolysis to overcome PET's unique challenges

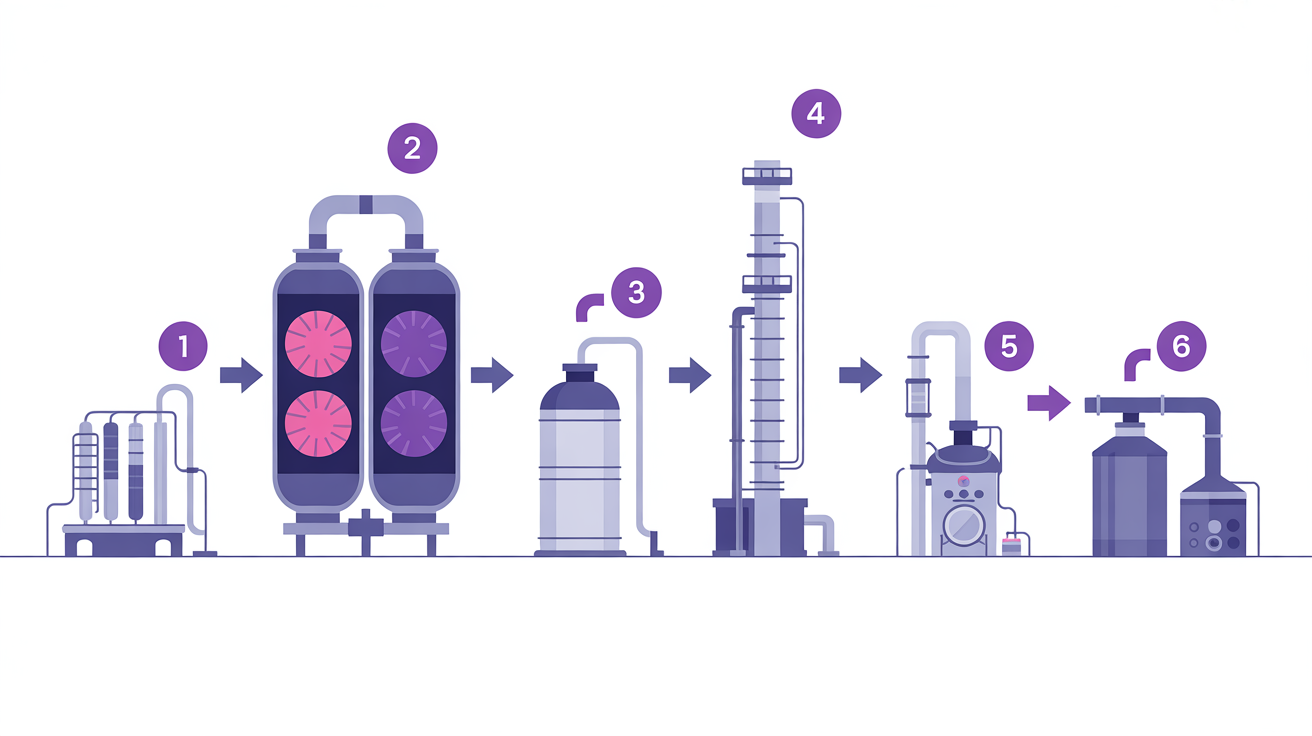

| Stage | Process Step | Description |

|---|---|---|

01 | Selective Partial GlycolysisPATENTED INNOVATION | PET undergoes controlled glycolysis at 150-180°C to produce BHET monomers and reactive oligomers |

02 | Dual-Zone Catalytic PyrolysisPATENTED INNOVATION | Zone 1: Fe-ZSM-5 catalyst for deoxygenation | Zone 2: Ni-Mo catalyst for hydrogenation |

03 | Vapor Separation | Hot separation removes non-condensables and heavy wax, optimizing downstream processing |

04 | Fractional Distillation | Kerosene-range (C₁₀-C₁₅) fraction isolated for jet fuel production |

05 | Hydrotreating (Reduced Severity)PATENTED INNOVATION | 40-60% lower hydrogen consumption thanks to pre-deoxygenation in Stage 2 |

06 | Hydroisomerization & Blending | Final conversion to ASTM D7566-compliant Sustainable Aviation Fuel |

Four breakthrough innovations that enable economical PET-to-SAF conversion

Partial depolymerization (30-50% BHET) creates reactive intermediates without costly full conversion

Optimized Fe/Al ratio (0.15-0.35) enables selective PET deoxygenation while preserving aromatics

Co-fed polyolefins provide hydrogen-rich species, eliminating external H₂ during pyrolysis

Spatial separation of deoxygenation (Zone 1) and hydrogenation (Zone 2) prevents catalyst poisoning

Performance metrics demonstrating breakthrough capability for high-PET feedstocks

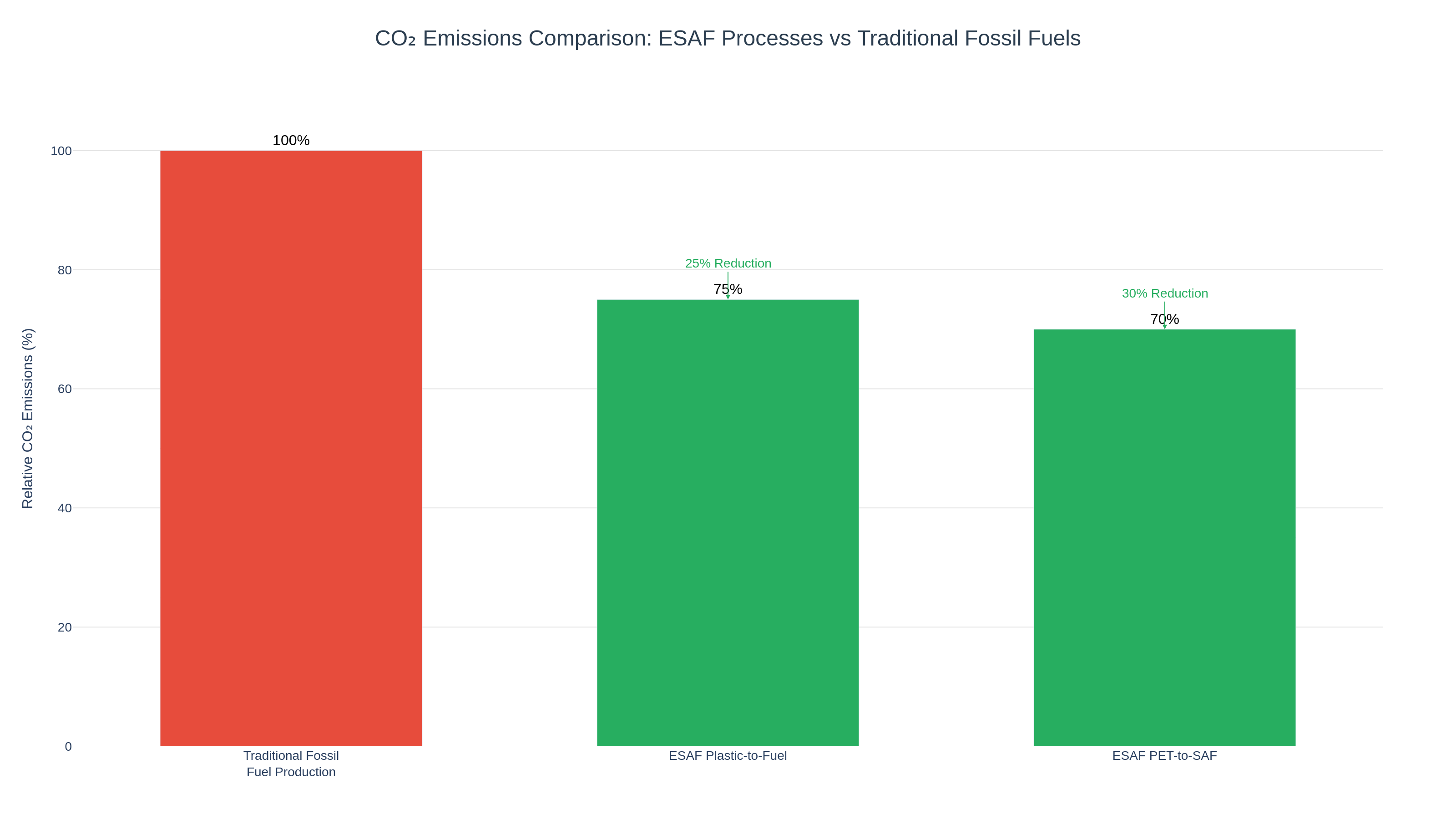

Converting difficult-to-recycle PET into sustainable aviation fuel with superior environmental benefits

ESAF TradeCo collaborates with Verra to establish dedicated methodologies for carbon credits and plastic credits generated from pyrolysis with PET-rich recycled feedstock, maximizing both environmental impact and economic returns.

First-of-its-kind technology enabling economical SAF production from PET-rich plastic waste

3-10x higher tolerance

2x better than conventional

dramatically lower costs

fully certified SAF